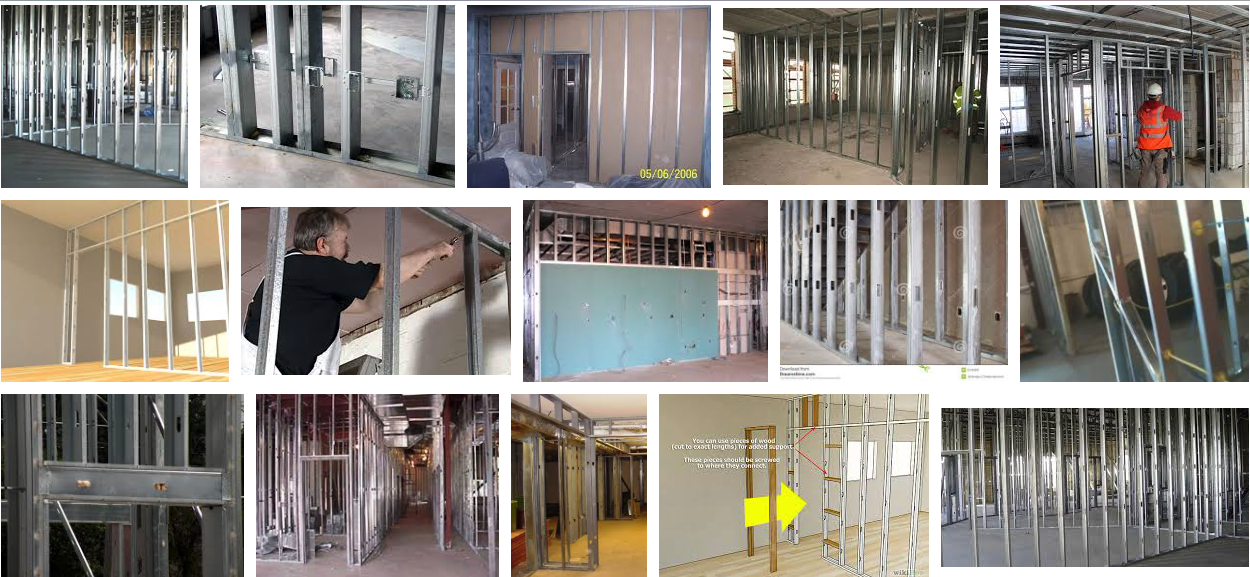

In this article we explain how to easily do metal stud framing and create wall partitions as well as discussing the benefits between using screws vs. metal stud crimpers.

How to install Gypwall partition

Gypframe studs are designed to interlock with each other so they can be extended. You should keep a minimum overlap of around 600mm when you are extending studs and you will need to fix the overlap with either gyprock wafer head screws or a stud interlocking tool.

On new concrete or screeded floors, consider adding a damp proof membrane between the channel and the floor to prevent the possibility of any corrosion happening on the floor channels.

Determine the wall position and make allowances for openings. Mark wall positions and doorways. For best practice, a bootleg detail can be installed.

At doorways, allowances for a timber sub-frame should be made. Alternatively, Gypframe studs and channels can provide a fixing for door casings.

Ensure studs are cut through a solid part of the stud and not through a section of it that has a cut out.

Locate the stud against the masonry wall installing proprietary fixings at 600mm centres and for wider gypframe studs, two rows of staggered fixings at 300mm centres. Locate further studs into position at 600mm centres.

Gypframe studs within the main run of wall are not fixed into position this allows adjustment during boarding of the partition.

At doorways, openings and external corners, the studs can be fixed in place with either a crimping tool or wafer head drywall screws.

Crimping vs screwing

When it comes to fixing metal frames together, there are two main methods: Using screws and a drill or using a crimping tool.

Screws are the traditional choice but some would argue that using a crimping tool is much quicker, easier and efficient as you are using less materials. It also eliminates the screw heads that can cause bumps/cracks within the wallboard.

Screws are often the choice for when it comes to exterior walls or interior bearing walls where the crimping tool’s is often disregarded for being insecure and the solidity and reliability of screws is favoured.

In some extreme cases it may be recommended to use both methods of both screws and a crimp. However, make sure you don’t put the screw through the crimped hole! You want to put the screw into a fresh part of the stud and track adjacent to the crimp itself. That way, you are getting two fastenings on the metal.

Completing Your Metal Stud Framing

Gypframe 72mm floor and ceiling drag is used for the head and sill of openings. The channel is cut 150mm wider than the opening at either sides.

This dimension is cut with tin snips and cloaked at either end of the doorway and fixed in place with either a crimping tool or gyproc wafer head drywall screws

Bear in mind that gyproc drywall screws are designed for fixing gyproc plasterboards onto the partition and are not designed for metal to metal fixings due to the size of the bugle head which sticks out on the surface. This can cause bursting of the plasterboard when boarding takes place.

For heavier studs and channels, gyproc wafer head jackpoint screws are used. This type of screw has a drill bit tip which pre drills before self tapping into heavier gage studs.

Apply gyproc sealant to both sides of the frame perimeter to provide optimum acoustic performance

Cut the gyproc 99fc 50 stud to length and simply flatten the flange on either side to allow a flush surface fixing with wafer head drywall screws.

Gyproc plasterboard joints are staggered on either side of the partition by 600mm so when you start boarding with a full board width of gyproc plasterboard, this will be staggered by starting with a 600mm wide gyproc wallboard on the opposite side.

Gyproc plasterboards are fixed at 300mm centres, with the appropriate length of gyproc drywall screw.

To determine the length of the gyproc drywall screw required add 10mm onto the thickness of the plasterboard and us the next screw size up to determine which drywall screw length to use.

Ensure you do not penetrate the board surface with gyproc drywall screws!

Where gyproc plasterboards have been raised off the floor to prevent the ingress of water during the construction, they should be filled with a proprietary gypsum based compound to maintain the best sound installation possible from the partition.

To lift the plasterboard off the floor you will need a versatile foot lifter to keep your hands free during the process.

To buy metal stud crimpers from leading brands head on over to https://www.gypsumtools.com/ or for more handy info on creating wall partitions using metal stud crimpers then check out this handy video