- Plastering Basics: Understanding Your Choices

- Advanced Plastering Options

- Pre-Plastering Considerations

- Troubleshooting Common Issues

- Types of Plastering Materials FAQs

Have you ever thought about all the different types of plastering materials you can use?

It can be a bit overwhelming!

Each type has its own special qualities that work well in different situations. Whether you want to make a room look nice, protect your walls from the weather, or create a peaceful and quiet space, there’s a plastering option that’s perfect for you.

Knowing about these choices will help you get the exact finish you want.

Plastering Basics: Understanding Your Choices

Choosing the right plastering material can feel like solving a tricky puzzle.

There are so many varieties, from old-school lime mixes to modern gypsum-based formulas. Each one has its own special qualities that work well in different situations.

To make the best choice, you need to consider things like durability, setting time, and the type of surface you’re working with.

It’s important to think about the specific needs of your project.

If you’re in a hurry, plasterboard adhesive with its quick setting time might be the way to go. On the other hand, if you’re working on an old building or a damp area, lime plaster’s breathability could be a big advantage.

The right plastering material is like a trusted partner, combining skillful application with the right formula to give you a finish that lasts.

Types of Plastering Materials

When it comes to plastering materials, it’s essential to understand the different types available to determine the best one for your specific project. Here are some common types of plastering materials:

Lime Plaster

Lime plaster is a traditional material that has been used for centuries. It is made by mixing lime, sand, and water.

Lime plaster offers excellent breathability, making it suitable for older buildings or areas where moisture control is important. It is also flexible and can withstand some movement without cracking.

Gypsum Plaster

Gypsum plaster, also known as plaster of Paris, is a popular choice for interior walls and ceilings. It is made by heating gypsum, a naturally occurring mineral, to remove the water content.

Gypsum plaster sets quickly and provides a smooth finish. It is fire-resistant and offers good sound insulation properties.

Cement Plaster

Cement plaster, also known as cement render, is a mixture of cement, sand, and water. It is commonly used for exterior walls and provides a strong, durable finish.

Cement plaster is weather-resistant and can withstand harsh conditions. It requires proper curing to prevent cracks and needs reinforcement on corners and junctions.

Clay Plaster

Clay plaster is an eco-friendly and breathable option for plastering. It is made from natural clay mixed with sand, fibres, and additives.

Clay plaster offers good thermal insulation and regulates humidity levels. It is particularly suitable for sustainable and energy-efficient buildings.

Synthetic Plaster

Synthetic plaster is a modern alternative that combines the benefits of different materials. It is a pre-mixed product that may contain a combination of cement, gypsum, or other additives.

Synthetic plaster offers faster application and drying times. It is often used for high-quality finishes and decorative purposes.

Selecting the Right Mix for Durability

When it comes to choosing a plaster mix, durability is important for long-lasting results.

If you have a high-moisture area, go for cement-based plasters. They’re water-resistant and can handle the dampness.

Gypsum plaster gives you a smooth finish and is often the go-to plaster material of choice, however it might not be the best choice for really wet conditions unless you add some extra stuff to it.

Lime plaster is great when it comes to durability. It works great for historical restorations as well as new buildings because it’s flexible and lets your walls breathe.

If you’re working on a project outside, or doing external rendering, acrylic plasters are the way to go. They’re tough and can handle the weather without cracking or wearing down.

Clay plaster is an eco-friendly option that is made from natural clay and sand. It is breathable, non-toxic, and has excellent thermal properties.

Make sure to find a balance between strength and flexibility. You don’t want to sacrifice one for the other and end up with expensive repairs later on.

Advanced Plastering Options

If you’re looking for the ultimate plastering finish, venetian plaster is a great choice. It’s made from crushed marble and lime, giving your walls a shiny, 3D look. Applying it takes serious skill and craftsmanship, with layer upon layer creating a timeless polished finish that’s both durable and stunning.

For a modern twist, you might want to check out magnetic plaster. It’s just like regular gypsum plaster in texture, but it has special magnetic properties. That means you can stick magnets to it! It’s perfect for turning your wall into a cool gallery or an interactive space. Magnetic plaster brings together functionality and style in your home or workplace. The possibilities are endless!

Thermal and Acoustic Solutions

When comparing different types of plastering materials, don’t forget about the thermal and acoustic properties. Choosing the right materials can make a big difference in the comfort and peacefulness of your spaces.

Some plastering materials have the ability to insulate against heat loss and reduce noise. For example, gypsum plasters with insulating additives can help you save on heating costs. And if you want a quieter environment, there are also additives that absorb sound vibrations.

For thermal insulation, there are plasters with perlite or vermiculite mixed in. These lightweight materials not only keep the heat in, but they’re also easy to apply. They can really boost the energy efficiency of your project if you use them right.

These materials combine the best of traditional plaster with modern technology, giving you a smooth finish and a functional barrier that makes your living spaces even better. If you incorporate these solutions early on, you’ll have a perfect balance of looks, comfort, and energy efficiency.

Eco-Friendly and Sustainable Practices

Being eco-friendly and sustainable is really important when it comes to plastering materials. Not only does it help the planet, but it’s also good for your health and your wallet.

If you want to make sure your living spaces are breathable and non-toxic, go for natural plasters. They create a healthier home environment.

There are lots of sustainable practices in plastering. Using recycled materials and applying natural lime and clay plasters are just a couple of examples. These practices reduce waste and give your space a unique and environmentally responsible look.

To make buildings last longer, we can use modern advancements like UV-resistant and breathable plasters. It’s crucial to think about sustainability from start to finish, from choosing the right materials to using the best techniques. That way, our constructions are not only strong, but also have a smaller ecological footprint.

As we keep up with new innovations, the focus on “green” in plastering is changing the way we build responsibly.

Pre-Plastering Considerations

Before you start plastering, it’s really important to carefully check the surface you’ll be working on.

Make sure it’s clean, stable, and free from dust or grease. This will help the plaster stick better and last longer.

If there are any structural problems, fix them before applying the plaster. Plastering over a damaged surface can cause issues down the line.

Also, think about the environment where you’re working. Humidity and temperature can affect how the plaster dries and the final result. So, choose the right plaster for the job to get the best outcome.

Surface Preparation Essentials

Properly preparing the surface is key to a successful plastering job. Here are some important steps to follow:

- Get it clean: Remove any dust, dirt, or debris. This helps the plaster stick better and gives you a smoother finish.

- Fix it up: Take care of any cracks, holes, or uneven spots. You want a solid surface for the plaster to adhere to.

- Prime time: If needed, apply a primer. This helps the plaster grip, especially on smooth or non-porous surfaces.

- Check for dryness: Make sure the surface is dry. Wet surfaces can cause the plaster to come loose or even grow mould.

- Tape it off: Use masking tape to protect any areas you don’t want to get plaster on. This keeps your work neat and precise.

Remember, taking the time to prepare the surface properly is crucial for a job well done. A clean and stable surface is like a blank canvas for your plastering skills.

Tools and Equipment for Efficient Application

Having the right tools in your toolbox is super important for getting that perfect plaster finish.

Here are some key essentials:

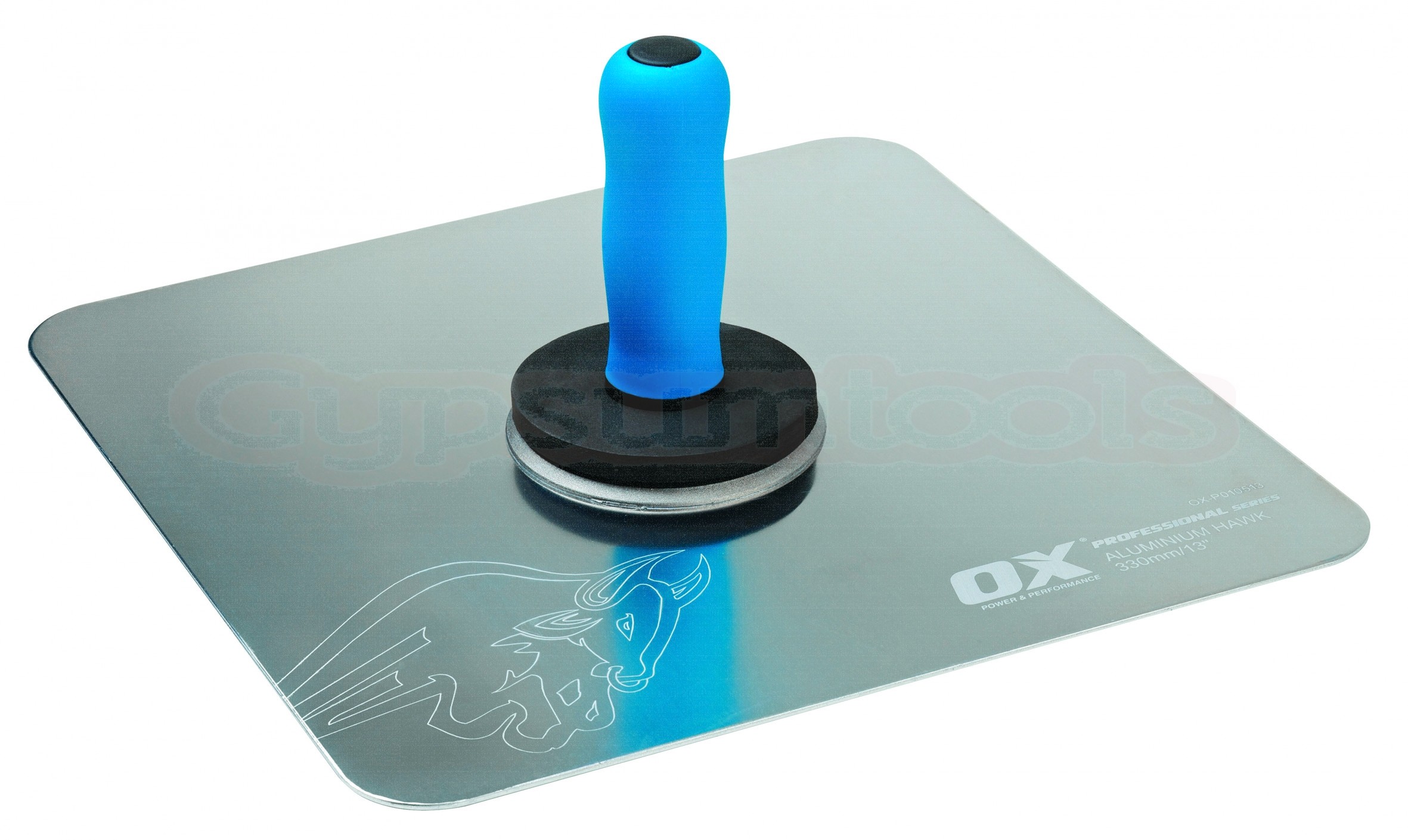

- Hawk and trowel: These are your go-to tools for applying plaster smoothly and evenly. They give you the support and control you need for a professional outcome.

- Mixing paddle or drill: You’ll need one of these to mix your plaster and get rid of any lumps. Make sure you choose a sturdy mixer for consistent results.

- Finishing trowels and feather edges: These tools help you apply the plaster with long, smooth strokes. They reduce the risk of leaving marks and help you achieve a flat and refined surface. Paying attention to detail here is what separates the amateurs from the pros.

- Corner trowels: These are great for creating perfect right angles and clean lines. They give your plastered edges a sharp and visually appealing look that shows off your expert craftsmanship.

- Variety of trowels: Pointing, gauging, and bucket trowels all have their own purposes in plastering. Having them in your toolkit ensures you can achieve a meticulous and high-quality finish.

Remember, in plastering having good quality tools is just as important as having the skills to use them.

Troubleshooting Common Issues

When plaster doesn’t stick well or starts flaking off, it’s usually because the surface wasn’t clean or primed properly.

It’s important to make sure the background is clean and prepped. Any dust, dirt, or grease can mess with the plaster’s ability to stick.

Moisture problems in the wall can also cause issues with adhesion. So, check for any dampness or residue from previous coverings before you start plastering.

If you see cracks or air bubbles after applying the plaster, it’s usually because you worked it too much or added too much air while mixing.

To avoid these problems, follow the instructions on the plaster mix and apply it with confidence.

Being hesitant can lead to these common issues that can be avoided.

Addressing Cracks and Efflorescence

Dealing with cracks in plaster is important to keep your walls looking smooth. You’ve got to fix those cracks right away to prevent them from getting worse.

Cracks happen for different reasons, like shifts in the structure, or not applying the plaster properly.

When you’re fixing cracks, you need to figure out what caused them first. If it’s a bigger problem with the structure, you might need to reinforce the wall before re-plastering. But if it’s just a small crack, you can fill it in and smooth it out to make it look nice again.

Efflorescence is a white powdery substance that shows up on your walls. It’s just salt coming out of the plaster.

It doesn’t hurt anything, but it doesn’t look good.

To get rid of it, you need to clean the wall really well and find out what’s causing the moisture that’s making it happen. Fixing the moisture problem will help keep the efflorescence from coming back.

Dealing with these issues is all about taking action at the right time and using the right materials and methods. Using the right fillers, treatments for efflorescence, and sealants can help a lot.

Learning how to mix and apply plaster correctly, as well as paying attention to the environment, can help prevent these problems from happening in the first place. That way, homeowners and professionals can keep their walls looking good and strong.

Preventing Moisture and Mould Growth

To keep moisture and mould away, you need a solid moisture barrier. Good ventilation is also important, especially in places like bathrooms and kitchens where humidity can be high.

Using anti-mould paints or additives on internal walls and ceilings is a smart move. It helps prevent mould from growing and keeps your home healthy and clean.

If you spot any leaks, fix them right away. That way, you can stop the conditions that mould loves before it has a chance to take hold.

Pay attention to signs like condensation and damp patches. They could be a sign of a bigger problem. Take action early to prevent mould from making itself at home.

Lastly, regular maintenance is key. Keep an eye out for any issues and clean things up before they become a big problem for your plasterwork.

Types of Plastering Materials FAQs

What is gypsum plaster and how is it used in plastering?

Gypsum plaster, also known as plaster of Paris, is a versatile material used in construction for plastering. It is a white powder obtained by heating gypsum to remove water. It can be mixed with water to form a paste for application on walls and ceilings.

Gypsum plaster is easy to apply, sets quickly, and provides a smooth finish. It is fire-resistant and offers sound insulation. However, it is not suitable for areas with constant water exposure.

What are the advantages and disadvantages of using lime plaster?

Lime plaster has advantages such as breathability, flexibility, durability, and eco-friendliness.

However, it requires specific skills, is more expensive, has a longer curing time, and may not be readily available. Consider these factors when choosing plaster for your home.

How does cement plaster differ from other types of plastering materials?

Cement plaster is a strong and durable plastering material that offers excellent adhesion and resistance to water damage. It is ideal for high-performance applications and areas exposed to moisture. However, proper skill and technique are required for application.

Overall, cement plaster can provide a long-lasting and visually appealing finish for your walls.

What are the characteristics of clay plaster and when is it used?

Clay plaster is a natural and versatile wall finish made from clay, sand, and other natural materials.

It is breathable, providing a healthy indoor environment, and offers excellent thermal insulation. It is durable, resistant to mould, and can be applied in various textures and finishes.

Clay plaster is suitable for new construction and renovations, making it a popular choice for eco-friendly and sustainable homes.

Are there any specific considerations for using plastering materials in exterior applications?

When using plastering materials for exterior applications, consider the climate, prepare the surface properly, choose the right plastering material, use appropriate tools, and perform regular maintenance. These steps ensure durability and a long-lasting finish.